Click

Here For Download of The Fedders A6Y18F7A-A Manual (892K PDF)![]() .

.

|

|

| How Air Conditioners Work &

When They Don't Work

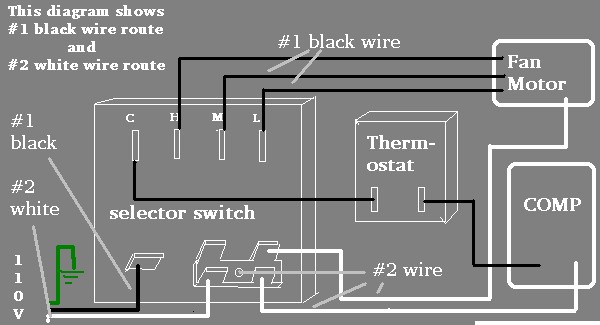

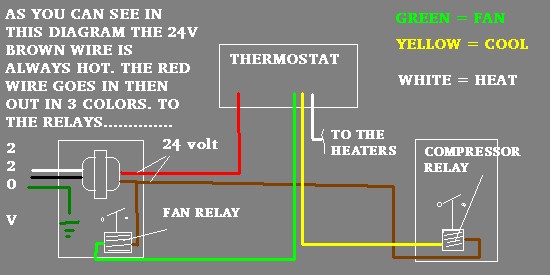

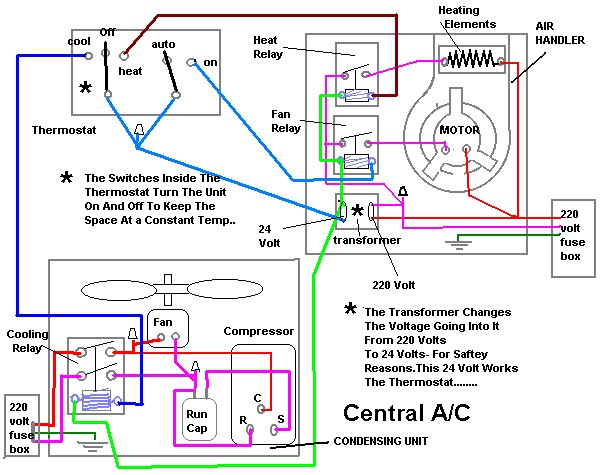

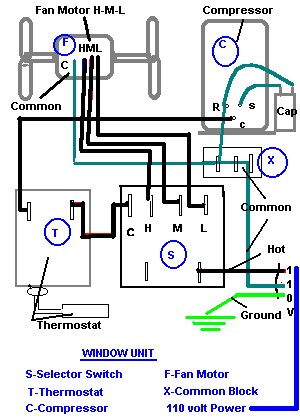

AIR CONDITIONING HELP**THIS IS FOR THE DO IT YOURSELFER WHEN THINGS HEAT UP To post a message or a question visit my message board Are you sweating and want to fix or at least learn about air conditioning, either home or car then you are at the right place. If your looking for AUTO air conditioning help go here. How to read and understand A/C gauges If you know that the problem is electrial ie. fan motor not running or everything isnt running then go here to my a/c electric page.

The main thing to remember is that all freon(refrigerants) work the same way no matter what is cooled, as in ice machines,de-humidifiers,freezers,coolers for flowers,ect. They all have a compressor, evaporator(cold coil), condensor(hot coil), expansion valve, and some way to remove the heat such as fans,water,buried underground,ect. They may use different refrigerants such as R-11,R-12,R-502,R-111,even ammonia Ammonia is somewhat different and dangerous so do not attempt to service these !!!!! "Freon" is also dangerous and you should take great care not to get any liquid freon on you as it will freeze your skin on contact, The vapors are not as dangerous though make sure your in a well ventalated area because it displaces the air in the room, meaning it collects in clouds you cannot see. Also when freon is burned (passes through a flame) it becomes toxic, when you smell something like an ammonia & bleach type smell its been burned and do not breath it. "Freon is also under pressure some systems it can be as high as 300 or more psi. HERE ARE SOME QUICK TIPS WHEN TROUBLE SHOOTINGCentral Air ConditioningFirst of all check the power to each unit (condenser*outside unit) Air handler (inside unit) for power, check the breakers or fuses on the inside of the house and there should be a breaker on or near the outside unit. Check and make sure that the fans (both) outside and inside are running If you have a package unit. The type that are on house trailers. The unit is all contained in one box with the duct work (2 duct hookups, in and out)the blower for the inside air is inside the box so just feel if any air is blowing out the ducts and the outside fan is running....P.S.-- if the cold coil is frozen than you won't feel any air blowing from the vents but the motor will still be running--. If you want to check to see if your inside air motor is running than turn your thermostat off, then click the fan switch to ON from the auto setting if its wired correctly you will hear the fan running inside the box.. The compresser must be running, it can be hard to hear if its running but they do have a buzzy type sound. Look for any ice on any of copper tubing, if you see ice then your a/c is frozen up (cold coil). One thing that is important is that the air coming out of the outside unit should be very warm unless you have a high efficient unit. w If you have a split system (unit outside & a air handler inside) then while your central air is running feel the temperature of the bigger of the two copper tubes that come out of the unit. The bigger tube should be cold like a cold soda can, and the little tube should be warmish.

Pressures on gauges...The readings on gauges are in pressure psi. If you look at the inside of the gauge there is a pressure temprature chart printed on the gauges for r-12, r-22, r-502. High and low side. Newer gauges have different charts. Lets look at a few examples.

If the pressure on an r-12 system on the low side, while the unit is running is 35 psi.(the outer black colored chart) then look at the smaller circles for the R-12 circle. The needle pointing to 35 psi. also crosses the R-12 circle, look at the corresponding number on it to determine what temperature the coil is operating at. It will be about 38 degrees F'. If your hi side on r-12 is at 160 psi. then look on the inner part of the gauge on the high side it will read about 120 degrees f. Lets look at r-22 on the gauge. If you have a low side of 68 psi. reading on your gauge then look at the inner chart for r-22 at 68 psi. it is about 38 degrees f. If you have a high side reading at 220 psi. then on your chart the gauge will read about 110 degrees f. The evaporator (cold coil) on any air conditioning system should never be below 32 degrees f. Why because the condensate (water) on the coil will freeze, freezing up the system. Freezers and refrigerators keep the temperature of the evaporator (cold coil) below freezing to keep the freezer cold enough to freeze. The coil operates at about 0 degrees f. So with the coil being that cold the condensate will turn to ice which will clog up the coil with ice. This will shut down the cooling. Refrigeraters have a defrost timer that turns on the heaters and shuts off the compressor. The timer keeps the defrost on for about 30-40 minutes. The thawing ice will drain down to the water pan under the frig to evaporate. If your system runs low on refrigerant it will freeze up because the lack of pressure means the evaporator (cold coil) will be under the 32 degree mark, thus freezing the water. It seems weird that if you loose refrigerant you would think that the system would warm up but thats not how it works. Think about it.

|

|

Temperature (F) |

134a (Psig) |

|

-60.0 |

21.6* |

|

-55.0 |

20.1* |

|

-50.0 |

18.5* |

|

-45.0 |

16.7* |

|

-40.0 |

14.6* |

|

-35.0 |

12.3* |

|

-30.0 |

9.7* |

|

-25.0 |

6.7* |

|

-20.0 |

3.5* |

|

-15.0 |

0.1 |

|

-10.0 |

2.0 |

|

-5.0 |

4.2 |

|

0 |

6.5 |

|

5.0 |

9.2 |

|

10.0 |

12.0 |

|

15.0 |

15.1 |

|

20.0 |

18.5 |

|

25.0 |

22.2 |

|

30.0 |

26.1 |

|

35.0 |

30.4 |

|

40.0 |

35.1 |

|

45.0 |

40.1 |

|

50.0 |

45.5 |

|

55.0 |

51.2 |

|

60.0 |

57.4 |

|

65.0 |

64.1 |

|

70.0 |

71.1 |

|

75.0 |

78.7 |

|

80.0 |

86.7 |

|

85.0 |

95.3 |

|

90.0 |

104.3 |

|

95.0 |

114.0 |

|

100.0 |

124.2 |

|

105.0 |

135.0 |

|

110.0 |

146.4 |

|

115.0 |

158.4 |

|

120.0 |

171.2 |

|

125.0 |

184.6 |

|

130.0 |

198.7 |

|

135.0 |

213.6 |

|

140.0 |

229.2 |

|

145.0 |

245.5 |

|

150.0 |

262.9 |

|

155.0 |

281.1 |

|

160.0 |

300.0 |

* - (in Hg) Vacuum